by Kiran Kumar Manga & Kencha Satya Umamaheswari

Summary

Establishing the commercial applications of zinc oxide (ZnO) nanoparticles requires robust antimicrobial testing, from lab-scale protocols to real-life scenarios. This study presents the antimicrobial evaluation of ZnO (ZArmour™) nanoparticles synthesised using an Annular Microreactor. Testing was conducted at the lab scale using SS150 protocols, with ZnO nanoparticles integrated into a commercial paint matrix. Real-life performance was assessed according to ISO 18593 standards. ZArmour™ demonstrated exceptional antimicrobial activity in both lab and field conditions, outperforming conventional organic-based additives. All data was verified and certified by third-party laboratories such as TVU.

Introduction

ZnO nanoparticles have garnered significant interest as alternatives to organic biocide additives in paint formulations, due to their strong antimicrobial activity. This efficacy is attributed to multiple mechanisms, including Zn²⁺ ion release, unique nanoparticle morphologies (flakes, stars, etc.), and the generation of reactive oxygen species (ROS) that disrupt microbial cell membranes. [1,2]

Studies show that ZnO nanoparticles exhibit broad-spectrum antimicrobial activity against Gram-negative bacteria (Escherichia coli, Pseudomonas aeruginosa), Gram-positive bacteria (Staphylococcus aureus, Bacillus subtilis), fungi, and even some viruses, making them suitable for use in healthcare and public spaces. [3]

Various methods are used to evaluate antimicrobial activity in paint systems. Common techniques include the zone of inhibition method, broth dilution tests for determining minimum inhibitory concentration (MIC), and real-world durability assessments simulating environmental exposure. [1]

Recent research emphasizes the importance of optimizing ZnO nanoparticle size, shape, and surface chemistry for compatibility with paint matrices. Nanostructured ZnO offers long-lasting antimicrobial activity without compromising paint quality, making it ideal for protective coatings.[4]

This study details the testing protocols and performance results for ZnO nanoparticles synthesised using an Annular Microreactor, compared to conventional organic biocides.

Methodologies

ZnO nanoparticles (ZArmour™) were synthesised using proprietary Annular Microreactor technology, integrated with AMLearn™, a machine-learning-based process optimisation platform. The reactor’s precise shear-rate control enables fine-tuning of particle size and morphology to produce high-quality ZnO nanoparticles.

| Criterion | Optimal Range/Requirement |

| Purity | ≥ 99% (low heavy metals) |

| Particle Size | < 100 nm |

| Morphology | Controlled (spherical, rod, or plate-like) |

| Antimicrobial Efficacy | Microbial growth reduction > 99.9% (ISO 22196) |

| Formulation Compatibility | Easily mixed with coating formulations |

| Toxicity | Low cytotoxicity, compliant with FDA/REACH |

| Environmental Safety | Eco-friendly synthesis, minimal environmental impact |

| Scalability | Maintaining quality at scale |

Table 1: Summary of Key Metrics for High-Quality Antimicrobial ZnO

Antimicrobial testing of ZnO/paint matrix

Lab-Scale Antifungal Testing (SS 150:2021)

SS 150:2021 is an industry-standard protocol for evaluating fungal resistance in biocidal coatings. To test ZArmour™, ZnO nanoparticles (1–2 wt%) were dispersed in a commercial paint matrix and bar-coated onto 32 × 32 mm Whatman filter paper. The samples were dried for 48 hours.

The fungal inoculum was prepared by suspending 1 µL of solid cultures of Aspergillus niger (ATCC 6295), Aspergillus oryzae (ATCC 10196), and Aureobasidium pullulans (ATCC 9348) into 10 mL of Potato Dextrose medium (39 g/L). The culture was incubated at 37 °C for 24 hours with shaking. Optical density was measured at 530 nm to determine inoculum concentration. A 0.1% SDS wetting agent was added to the cultured inoculum.

Each ZnO/paint-coated substrate was placed on a Potato Dextrose Agar plate and 1 mL of SDS-inoculated fungal solution was poured over it. The plates were dried in a Bio safety cabinet (BSC) for 40 minutes and then incubated upside down for 7 days.

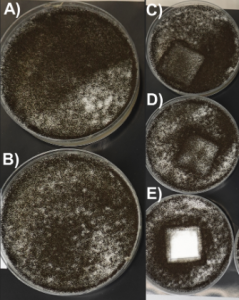

Figure 1: Upright position of inoculated substrates after five days of incubation. Potato Dextrose Agar plate without testing substrate (A), Agar plate with blank testing substrate (B), Commercial paint only coated substrate (C), Paint sample mixed with commercial ZnO (D), Paint sample mixed with ZArmourTM (E).

Figure 1 shows fungal growth after incubation. ZArmour™-coated samples (E1) displayed complete inhibition, while commercial ZnO-spiked (D1) and blank paint samples (C1) exhibited significant fungal growth. The superior performance of ZArmour™ is attributed to its crystalline flake structure, enabled by the precise shear control of the Annular Microreactor.

Field Testing (ISO 18593)

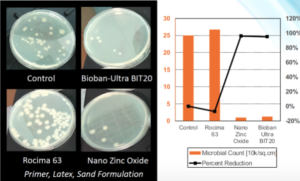

To evaluate ZArmour™ under real-world conditions, antifungal tests were conducted on a public walkway following ISO 18593 protocols. Paint formulations containing ZArmour™, Rocima, Bioban, and no biocide (control) were coated over 10 × 10 cm zones.

Figure 2: Field test conducted on a walkway surface using different biocides spiked commercial paint formulation coated on a walkway surface to test the antifungal performance.

After four months of outdoor exposure, fungal cells were extracted from each test zone using cotton swabs (Figure 3). The samples were cultured in nutrient broth and incubated on agar plates.

Figure 3:. Extraction of fungal cells from testing zone and culture them on agar plate for quantitative analysis of fungal growth.

Figure 4 shows that ZArmour™ achieved >99% fungal reduction, comparable to Bioban. Rocima showed some microbial growth, possibly due to non-fouling microbial cells. Control samples displayed no inhibition.

Figure 4: Quantitative analysis of fungal growth on different biocides/paint coated surfaces.

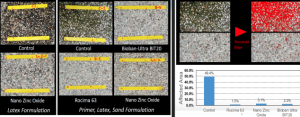

Figure 5 presents a visual inspection using image colour analysis. Fungal growth (red areas) covered only ~3% of the ZArmour™ coated surface after four months, comparable to Rocima and Bioban. In contrast, the control (paint-only) zone showed ~50% coverage.

Figure 5: Visual inspection of biocides/paint coated walkway surfaces after four months of coating. Fungal affected area calculated based on difference in colour contrast (red vs no colour) as shown in the image.

These results confirm the long-term durability and antifungal efficacy of ZArmour™ in real-world conditions.

Conclusion

This study evaluated the antifungal performance of nano-ZnO (ZArmour™) synthesised using an Annular Microreactor through both lab-scale (SS 150) and field-scale (ISO 18593) protocols. ZArmour™ demonstrated >99% fungal inhibition in laboratory settings and long-term resistance (over 4 months) in outdoor environments.

Thanks to its flake-like crystalline structure and precisely controlled particle size, ZArmour™ offers a high-performance, durable solution for antimicrobial coatings. Compared to organic biocides, ZnO is non-toxic, UV-stable, and environmentally friendly.

The integration of the Annular Microreactor with AMLearn™ positions this platform as a low-cost, sustainable, and scalable manufacturing solution for next-generation ZnO-based antimicrobial products.

References

- Gudkov SV, Burmistrov DE, Serov DA, Rebezov MB, Semenova AA and Lisitsyn AB A Mini Review of Antibacterial Properties of ZnO Nanoparticles. Front. Phys. 9:641481 (2021).

- Babayevska, N., Przysiecka, Ł., Iatsunskyi, I. ZnO size and shape effect on antibacterial activity and cytotoxicity profile. Sci Rep 12, 8148 (2022).

- Mendes, C.R., Dilarri, G., Forsan, C.F. Antibacterial action and target mechanisms of zinc oxide nanoparticles against bacterial pathogens. Sci Rep 12, 2658 (2022).

- El-Habib, I., Maatouk, H., Lemarchand, A., Dine, S., Roynette, A., Mielcarek, C., Traoré, M., & Azouani, R. Antibacterial Size Effect of ZnO Nanoparticles and Their Role as Additives in Emulsion Waterborne Paint. Journal of Functional Biomaterials, 15(7), 195 (2024).