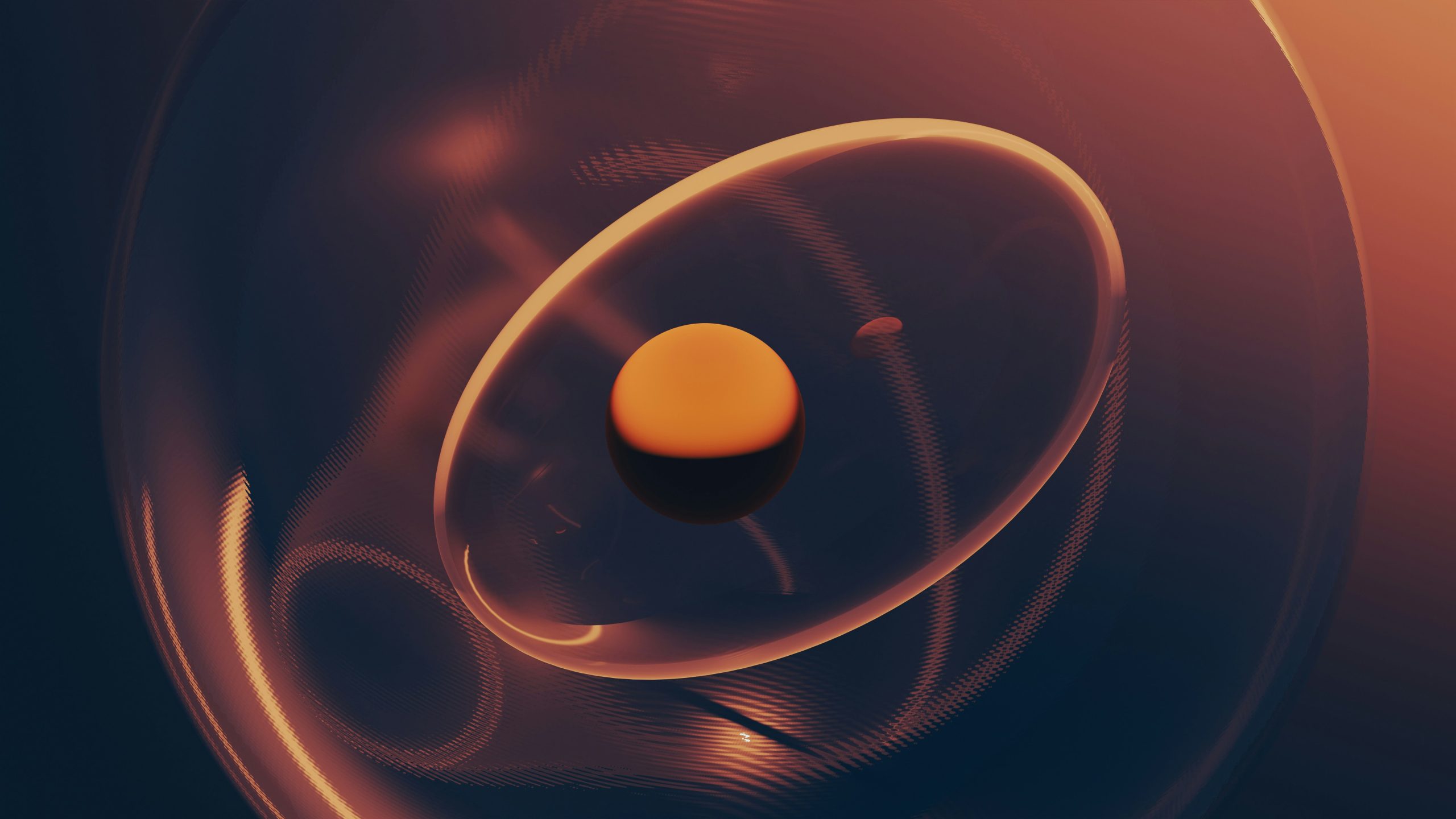

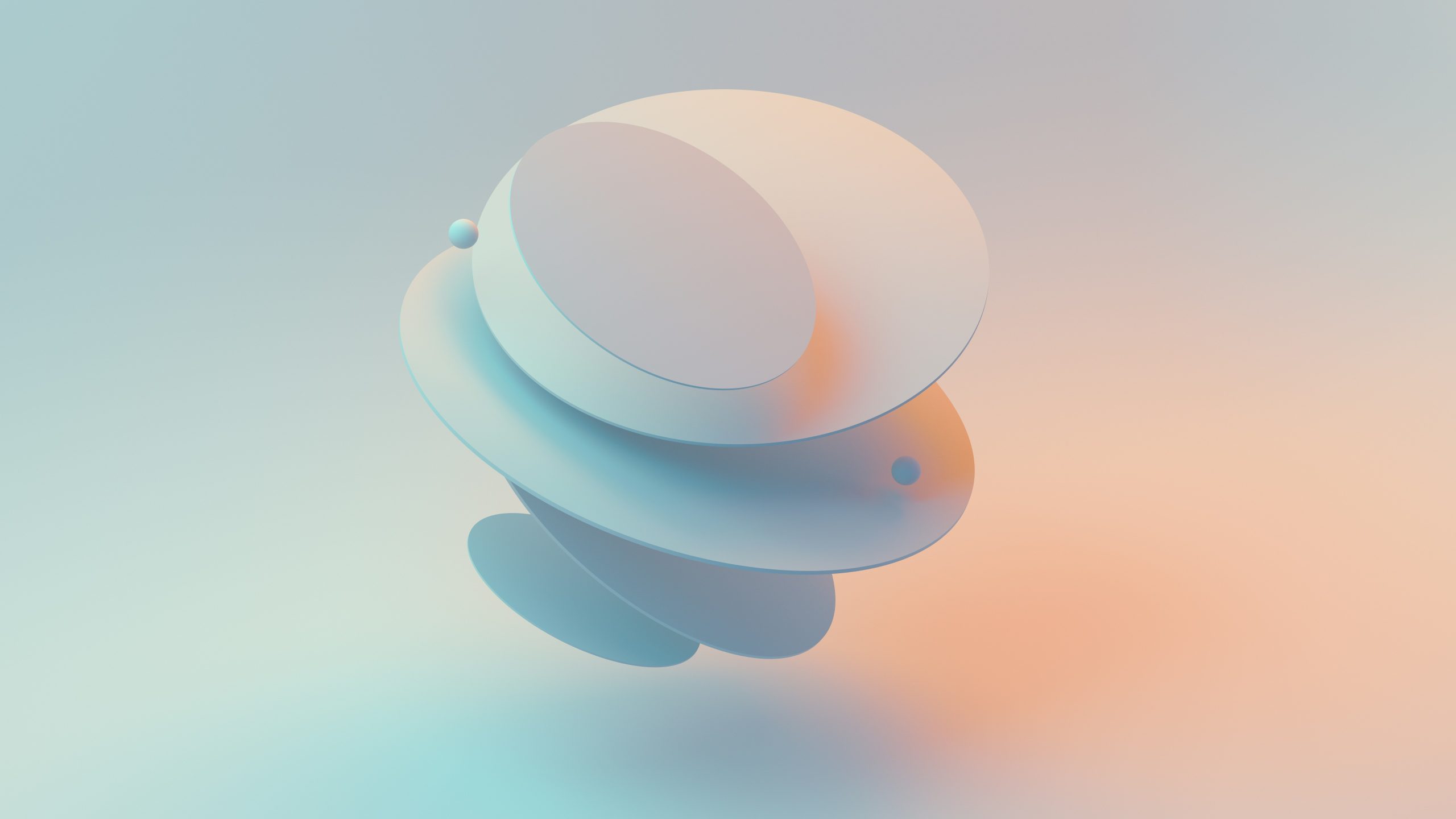

The Annular Microreactor

The annular microreactor uses a unique, high-velocity gas and liquid flow to synthesize nanoparticles. It forces liquids into a thin film with high shear force, providing exceptional mixing and control over nanoparticle properties. By controlling nanoscale phenomena of hydrodynamic assembly, this reactor enables users to precisely manipulate particle size and shape just by flowrate control. This approach also prevents clogging, allowing for continuous and scalable production, unlike costly and inconsistent batch methods.

This core technology is a key component of the Accelerated Materials platform for faster materials discovery and process scaleability. The Annular Microreactor is a key component of AM’s K-series reactors.