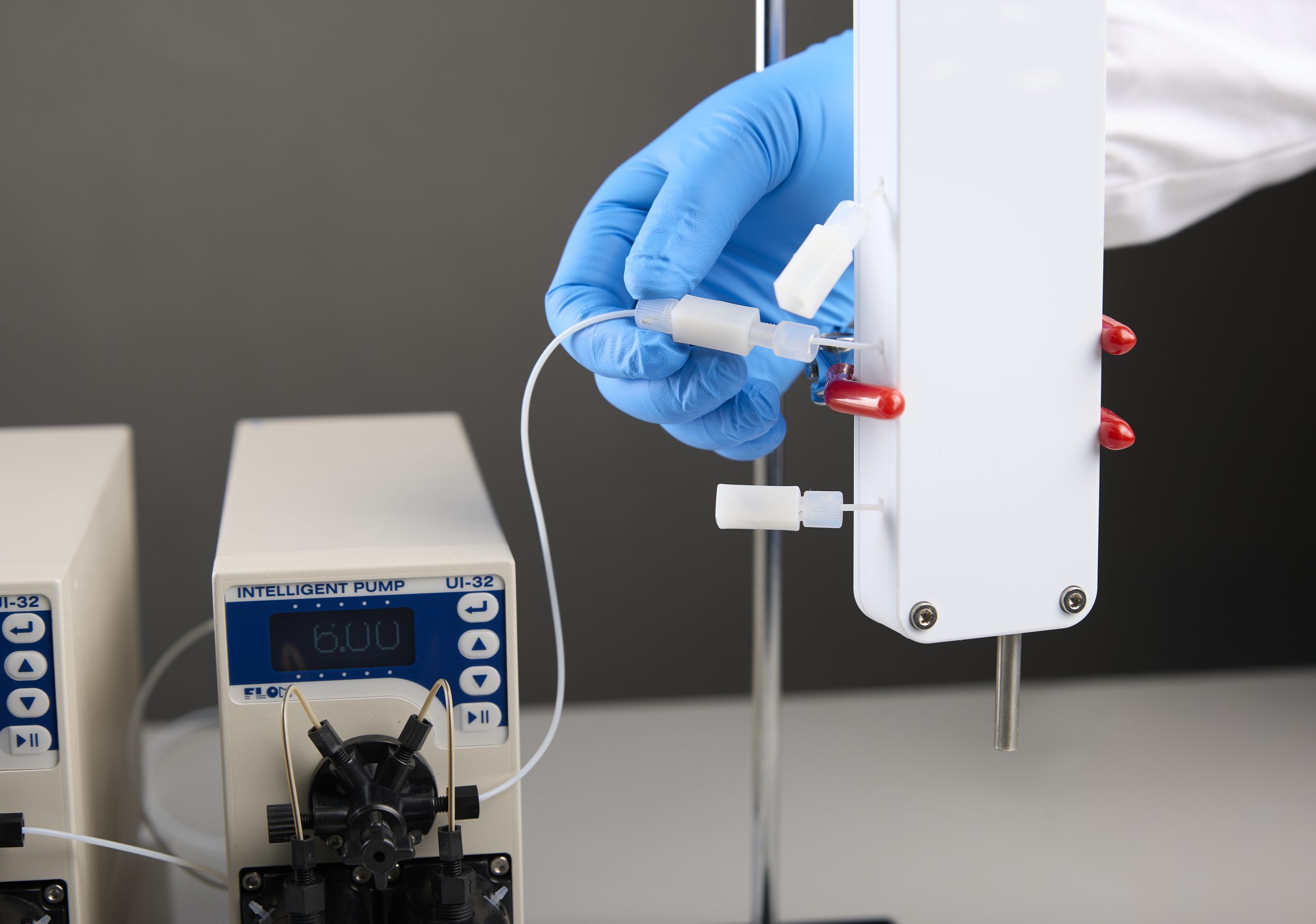

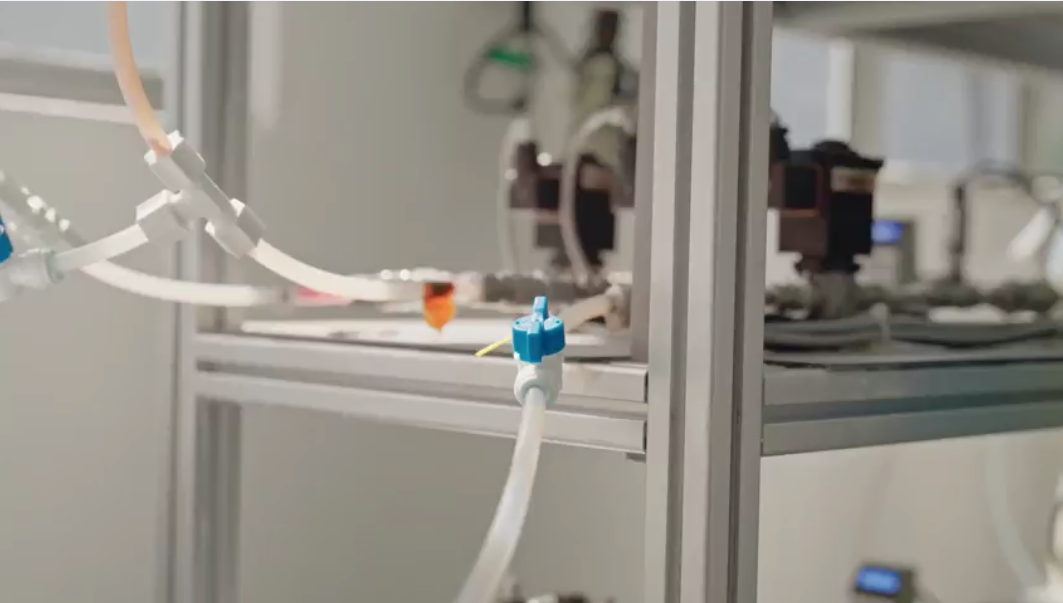

The K-Series

The K-Series is a microreactor platform which offers unparalleled performance across for the synthesis of the nanomaterials from lab to manufacture.

Our K-Series continuous-flow reactors make it easy to scale nanomaterial products with unmatched precision and reproducibility. Whether you’re producing grams for R&D or scaling to hundreds of kilograms per day, the K-Series ensures consistent quality and efficiency at every step.